Discover essential tips on selecting the right parts, understanding engine assembly, and ensuring proper alignment for optimal engine performance.Building an LS3 engine can be an exciting yet daunting task for beginners. With its impressive performance potential and versatility, this engine platform has captured the attention of automotive enthusiasts worldwide. However, navigating through the intricate process of selecting the right parts and assembling the engine can be overwhelming for those just starting out. In this blog post, we’ll break down essential tips to help you through your LS3 engine build journey. From choosing compatible components that enhance performance to understanding the assembly steps that ensure a smooth operation, we’ve got you covered. Additionally, we’ll share valuable insights on maintaining proper engine alignment—a critical factor that can make or break your project’s success. Whether you’re a novice or eager to refine your skills, this guide will empower you to tackle your first LS3 build with confidence!

Choosing the Right Parts

When embarking on your LS3 engine build, selecting the right parts is critical for achieving optimal performance and reliability. With a plethora of options available on the market, beginners may find themselves overwhelmed. Here’s a guide to help you navigate the essential components you need for your build.

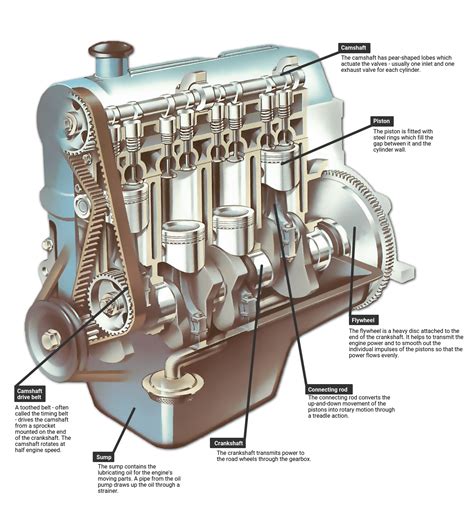

First and foremost, focus on acquiring a quality engine block. The LS3 block is made from aluminum, which offers a great balance between weight and strength. Pairing it with reliable internal components is equally important. Consider investing in high-performance pistons and rods that can withstand higher RPMs and increased power output.

Next, don’t underestimate the value of selecting the right camshaft. A performance camshaft will not only enhance engine efficiency but also elevate the overall horsepower and torque figures. Be sure to choose a cam profile that aligns with your desired performance goals. Additionally, opt for an appropriate intake manifold and fuel injectors to maximize airflow and fuel delivery, ensuring the engine runs optimally.

| Part | Key Considerations |

|---|---|

| Engine Block | Material, weight, strength |

| Pistons and Rods | Durability, performance rating |

| Camshaft | Performance goals, RPM range |

| Intake Manifold | Airflow capacity |

| Fuel Injectors | Flow rate, compatibility |

Understanding Engine Assembly Steps

As you embark on your journey of building an LS3 engine, understanding the assembly process is crucial for a successful outcome. Each step in the assembly should be performed with precision and care to ensure optimal performance and reliability. Here, we will break down the essential steps involved in assembling your LS3 engine.

First, it is vital to begin with a clean and organized workspace. Gather all the necessary tools and parts, including the block, {cylinder heads, and moving components. These include pistons, crankshafts, and connecting rods. Make sure each part is compatible with the overall build; mismatched components can cause significant issues down the line.

Once your workspace is prepared, begin the assembly by following these simplified steps:

| Step | Description |

|---|---|

| 1 | Prepare the engine block and inspect for any damage. |

| 2 | Install the crankshaft and ensure proper alignment. |

| 3 | Attach the connecting rods and pistons to the crankshaft. |

| 4 | Install cylinder heads with new gaskets for a secure fit. |

| 5 | Finally, add the intake manifold and wiring before sealing the engine. |

Keep these steps in mind as you work through the assembly of your LS3 engine. Check alignment and torque specifications meticulously during the process to avoid any potential issues. Following these guidelines will set you on the rig

Tips for Ensuring Proper Engine Alignment

When it comes to building an LS3 engine, ensuring proper engine alignment is crucial for optimal performance and longevity. Misalignment can lead to serious issues such as excessive wear, increased friction, and even catastrophic engine failure. Below are some vital tips to help beginners ensure their engine components are aligned correctly.

One key aspect of proper engine alignment is to utilize a high-quality engine hoist and level the engine during the installation process. This will help maintain the ideal position for various components, such as the crankshaft and cylinder heads. Make sure to double-check all mounting points to ensure everything is straight and properly secured.

Additionally, consider using alignment tools like a dial indicator or a laser alignment tool. These devices can help you measure and confirm that the crankshaft is aligned with the transmission input shaft. Doing so can prevent unnecessary wear on the flywheel and flexplate, which are essential for smooth operation.

Remember, a well-aligned engine not only enhances performance but also reinforces the integrity of your build. Take the time to ensure everything fits together perfectly.

Lastly, after assembling your engine, don’t hesitate to take it for a test run. Monitor for any vibrations or unusual noises, which can indicate alignment issues. Fine-tuning the alignment can be a tedious process, but it is essential for maintaining the health of your LS3 engine.

Frequently Asked Questions

What is the LS3 engine?

What is the LS3 engine?

The LS3 engine is a 6.2-liter V8 engine produced by General Motors, known for its high performance and versatility in various applications, especially in sports cars and trucks.

What tools do I need for an LS3 engine build?

Essential tools include basic hand tools like sockets and wrenches, a torque wrench, engine stand, lift, and specialized tools like a ring compressor and camshaft alignment tool.

How do I prepare the engine block for building?

To prepare the engine block, clean all surfaces thoroughly, inspect for any damage or wear, and ensure that all oil passages are clear. It’s also important to check the deck for flatness.

What should I consider when choosing parts for an LS3 build?

Consider factors such as your performance goals, budget, compatibility of parts, quality of components, and whether you’re aiming for street performance or track use.

How important is tuning after an LS3 engine build?

Tuning is crucial after an LS3 engine build to ensure the engine runs efficiently and safely, maximizing performance while preventing issues like detonation and overheating.

What are common mistakes to avoid in an LS3 build?

Common mistakes include rushing the assembly, not using the right torque settings, failing to check clearances, and neglecting to properly clean and prepare parts.

Can I use aftermarket parts in my LS3 build?

Yes, aftermarket parts can offer improved performance and customization options, but it’s essential to ensure they are of high quality and compatible with your engine setup.

| Tips for Engine Alignment | Benefit |

|---|---|

| Use a high-quality engine hoist | Ensures correct positioning |

| Employ alignment tools | Accurate alignment measurement |

| Conduct a test run |